-

Planning and Project Definition Risk Assessment; Design Brief; Reliability and Quality Objectives;

-

Product Design and Development DEMFA; Drawings and Specifications;

-

Process Design and Development Process Flowchart; PFMEA; MSA Plan; PPK Plan;

-

Product and Process Confirmation QC Engineering Drawings; MSA Analysis; PPK Analysis; Quality Planning Verification; PPAP Submission;

-

Process Evaluation and Continuous Improvement SPC; 8D;

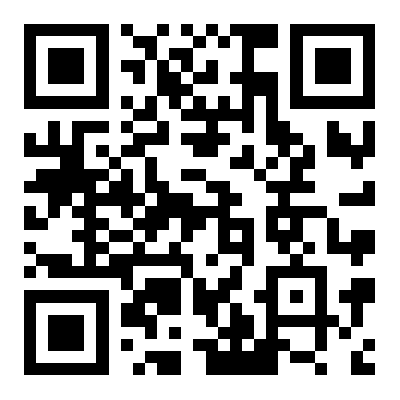

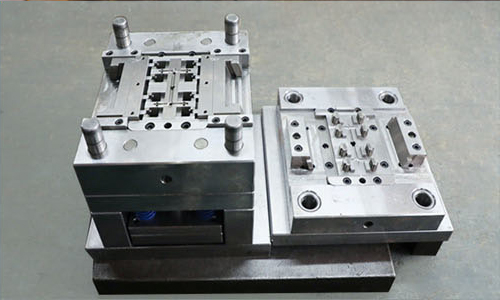

Liyang's mold processing equipment includes CNC machine tools, precision grinders, slow wire cutting machines, wire EDM machines, electrical discharge machining machines, and precision parts processing measurement.

Mold development technology includes plastic mold design and development as well as hardware mold design and development.

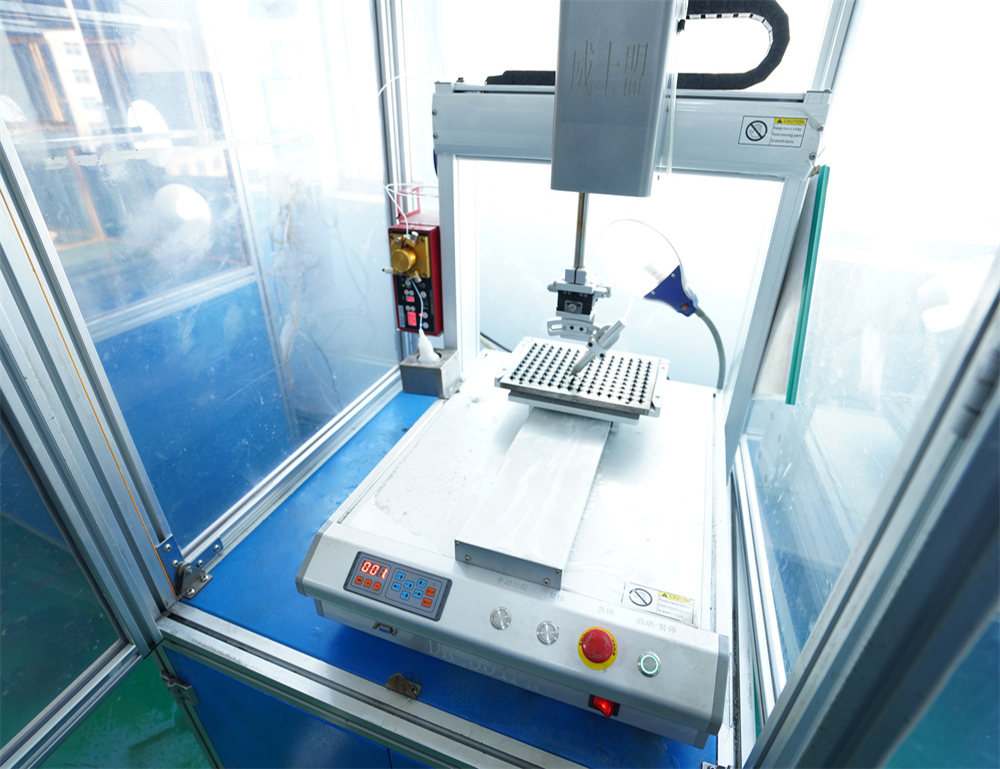

Network Socket Automation Equipment

Network Socket Automation Equipment

HDMI Automation Equipment

HDMI Automation Equipment

Touch Switch Automation Equipment

Touch Switch Automation Equipment

-

Environmental Testing High and Low Temperature Testing, Temperature Cycle Testing, Constant Humidity and Heat Testing, Salt Spray Testing, Thermal Shock Testing

-

Wire Harness Performance Testing Wire Harness Swing Testing

-

Durability Testing Mechanical Life Testing, Vibration Testing, Electrical Life Testing

-

Welding Performance Testing Solderability Testing, Resistance to Soldering Heat Testing

-

Mechanical Performance Testing Insertion and Extraction Force Testing, Actuation Force Testing

-

Conventional Electrical Performance Testing Contact Resistance Testing, Insulation Resistance Testing, Dielectric Strength Testing

-

LED Testing LED Optoelectronic Testing, HSL Testing

-

Environmental Testing RoHS Testing, HF Testing, Red Phosphorus Testing, Plating Thickness Testing